The growing focus on sustainability and health has given rise to an entire sector dedicated to food experimentation: that of the new feeds. Here research, agriculture and technology meet to develop new sources of nutrients that meet the needs of an ever-changing world.

The so-called novel food - or “novel foods” - include innovative ingredients such as edible insects (crickets, grasshoppers), algae (spirulina, chlorella), proteins from mushrooms or even laboratory-grown meat. The aim is to provide more sustainable protein alternatives, reducing the environmental impact compared to traditional production.

Before reaching the market, each novel food is carefully assessed by the competent authorities, to ensure its safety and compliance with European regulations.

Drying at a low temperature allows preserving nutritional value of the most delicate raw materials and to obtain stable, safe and easily storable ingredients, ideal for testing, production and marketing.

This is a natural, precise and repeatable process that allows the quality of novel foods to be standardised without resorting to invasive or industrial processes.

▸ La ferme du Courtis Flamand, Moringhen (France)

«Eravamo consapevoli che per ottenere un prodotto di qualità avremmo dovuto avvalerci di un processo specifico per non degradare il cibo e per mantenerne i valori nutrizionali. L’essiccatore offre velocità, semplicità e sicurezza per la lavorazione delle alghe»

- Rachel Obaton

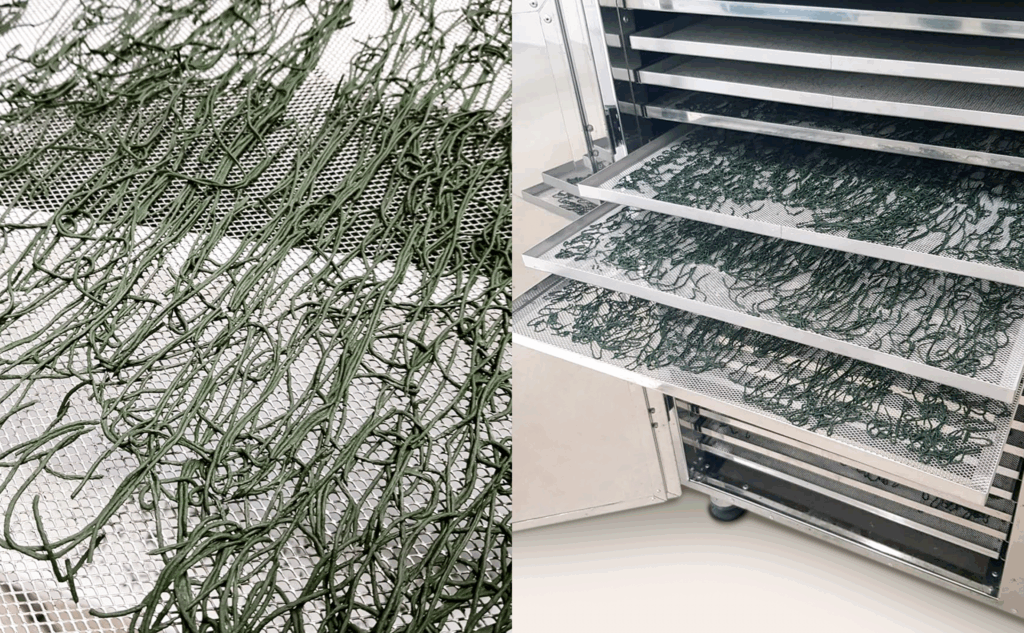

Spirulina algae.

Pasta, spaghetti e persino sfoglie di lasagne alla spirulina

When we started, we knew that in order to obtain a quality product, we needed a process that would not degrade the food and maintain its properties. We were looking for an optimised way to dry spirulina at low temperature and discovered Tauro through social media and the experience of a colleague in the south of France.

Many companies simply dry spirulina in dedicated rooms, but the dryer offers speed, simplicity and security in the treatment of algae.

We are very active in the media and social networks - radio, press, blogs, website, influencers - to promote our spirulina, which is sold directly in the company, online and through delicatessens and organic shops.

We also collaborate with food companies that make pasta, spaghetti and even spirulina lasagne sheets, and participate in fairs dedicated to wellness and natural gastronomy.

In the world of new feeds, drying represents a key technology for the preservation and enhancement of innovative ingredients. It allows:

Vuoi una soluzione naturale e sostenibile, perfettamente in linea con la filosofia di chi lavora oggi per building the food of the future?

Ti aiutiamo a selezionare macchinari, pianificare i cicli di essiccazione e ottimizzare processi.

👉 Scopri le soluzioni professionali più adatte alla tua idea di business.

Drying means dehydrate, that is, subtracting from a food its share of water, which is often the bulk of its weight.

In this way, the raw material changes its appearance slightly, but retains - or rather concentrates - its organoleptic and nutritional properties.

Not only that: removing water decomposition and oxidation processes are stopped or drastically slowed down, and the shelf life of the product is greatly extended. from perishable to durable. This greatly simplifies logistics management, storage and sales.

Drying therefore allows preserve food better and longer, preserving its flavour and nutritional qualities.

You can drying and transform:

- fruit

- small fruits

- oily fruit

- aromatic herbs

- medicinal herbs

- flowers

- spices

- saffron

– spirulina

– alghe e microalghe

- fungi

- grain

- noodles

- meat

- fish

– trebbie di birra

– bucce e vinacce

– proteine alternative

You can obtain and commercialise:

- fruit and vegetable chips and snacks

- flavoured powders and salts, flavourings

- spices, herbs and edible flowers

- crispy sheets (leather) of fruit or vegetables

- dehydrated vegetables and soups

- ready meals and preparations for cooking

- energy bars

- fresh pasta

– farine

- infusions

- pet food

Yes, in order to market, sell or administer processed products, it is necessary to operate in a laboratory that is recognised by the health authorities (HACCP), even if it is small or located within the company.

Absolutely. Many facilities start with small quantities to test recipes, snacks or flavour powders before expanding production.

Yes. Drying makes it possible to reduce waste, valorise surpluses and offer natural products with low costs and a concrete economic return.

If you have a farm, drying is an optimal and efficient way to enhance the 100% of your production. You can process products grown by yourself or by third companies with whom you can create network synergies.

You get several benefits, all related:

- zero waste and convert surpluses into a long-term resource

- give a destination to aesthetically imperfect or damaged products by hailstorms or (increasingly frequent) frost, which you would not be able to sell otherwise

- diversify your business and minimise business risk

- increase the catalogue of your offer and distinguish yourself by competitors

- you can sell is directly to the final purchaser, in person and online; but also to retailers such as e-commerce, shops, farms and restaurants.

In general, the advantages of dried products are many.

If you make or trade dried products:

- obtain or resell food with a high shelf life (shelf life)

- greatly simplify the logistical management of your offer, from warehouse to sale

- create a line of healthy products without added sugar or preservatives, of course rich in fibre and nutrients

- conquer a steadily growing slice of the market, which demands healthy, artisanal and ready-to-eat products